Revolutionizing Manufacturing: the Transformative Power of AI

In our previous blog, we embarked on an enlightening journey, exploring the transformative potential of Artificial Intelligence (AI) in the realm of agriculture. We discussed how AI could provide farmers with a treasure trove of data-driven insights and ground-breaking innovations, significantly changing how crops are grown, cared for, and harvested. AI’s impact is revolutionizing the once traditional agricultural landscape, leading to a technological leap.

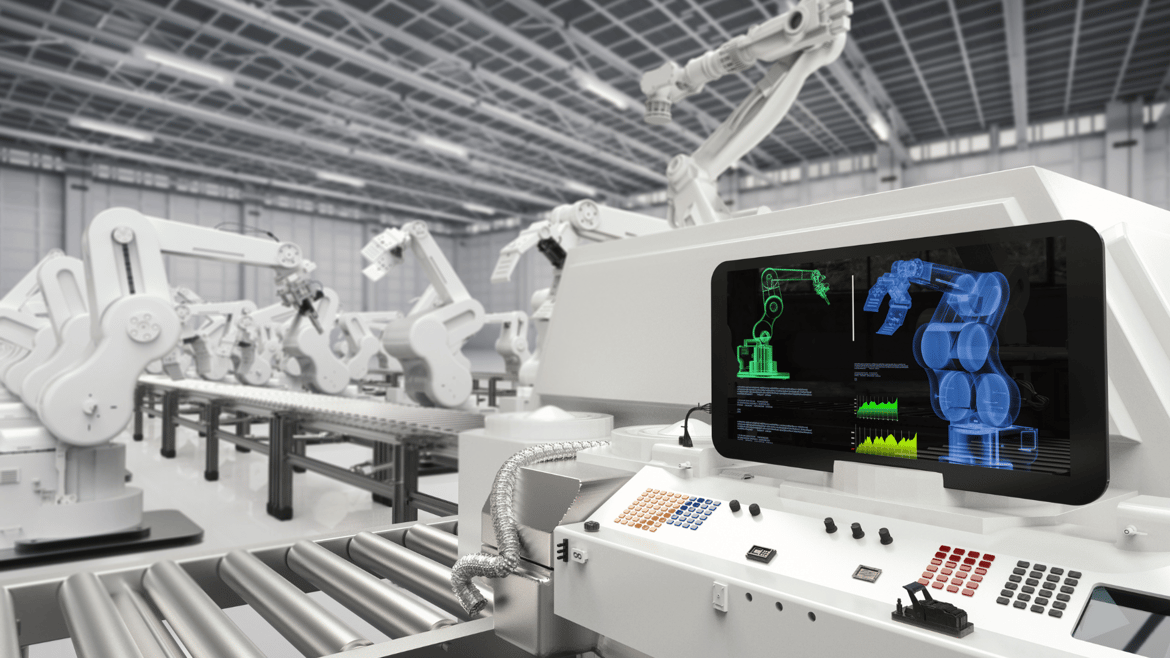

Continuing our exploration, this blog shifts its focus to manufacturing, another pivotal industry experiencing a transformative revolution. We will delve into how AI, a tool quickly becoming a catalyst for revolutionary change, could reshape manufacturing processes, enhance productivity, and optimize resource allocation. Join us in envisioning a future where manufacturing is ‘intelligized’ through the power of AI, surpassing mere mechanization.

AI: A Revolutionary Force in Manufacturing

The adoption of software technologies in manufacturing has been traditionally slow for various reasons. Predominant among these is the view of manufacturing as a hardware-centric industry reliant on machinery and human labor. Financial constraints, inadequate digital infrastructure, and a lack of technological literacy also contributed to a slower digital transition. However, AI’s advent compels manufacturing to embrace transformative digital solutions.

The shift in potential value of generative AI in areas like manufacturing and supply chain management may indeed be lower, prompting the manufacturing industry to seek other AI solutions. However, the buzz around generative AI is not without merit. Although not the primary driver, AI’s broad capabilities raise awareness and spark interest in manufacturing. This awareness can inspire manufacturers to explore AI applications beyond traditional use cases.

The Momentum Behind AI Adoption in Manufacturing

AI in manufacturing refers to the ability of machines to perform tasks in an autonomous manner similar to human beings, responding and even anticipating both internal and external events. It enables machines to detect issues, such as tool wear or unexpected events, and react accordingly. As computing technology continues to evolve, AI has become a natural progression, augmenting human capabilities rather than replacing them. It’s increasingly about human-robot collaboration, with AI-driven innovations making these collaborations safer and more efficient. The current applications of AI in the manufacturing industry are mostly concentrated in measurement, nondestructive testing (NDT), and design. However, the adoption of AI in fabrication is still in the early stages.

Several factors are propelling AI’s acceptance in the manufacturing sector. Foremost among these is the increased availability and affordability of digital infrastructure. The digital divide is narrowing with widespread smartphone usage, internet connectivity, and the Industrial Internet of Things (IIoT).This digital shift is paving the way for software technologies, including AI, to be incorporated into manufacturing systems.

Big data in manufacturing, along with sensors, automation, real-time monitoring, and data analytics, offers manufacturers valuable insights. AI harnesses this information to optimize processes, reduce waste, and enhance efficiency.

Additionally, the rising global demand for high-quality, sustainably produced goods has amplified the urgency for AI adoption in manufacturing. AI drives energy efficiency, waste reduction, and sustainable sourcing in manufacturing. This happens through precision techniques and resource optimization.

AI Use Cases in Manufacturing

AI is significantly influencing the manufacturing industry. Its role in predictive maintenance is crucial, analyzing continuous data streams from sensors to anticipate potential problems before they occur. Moreover, it enhances additive manufacturing and facilitates precise process design and problem diagnosis through digital twins. Both large enterprises and small-to-medium enterprises (SMEs) are embracing AI to remain competitive. Projects such as DRAMA (Digital Reconfigurable Additive Manufacturing facilities for Aerospace) highlight the ongoing progress in the realm of AI in manufacturing.

The increasing use of AI technologies has revolutionized operations and increased efficiency in factories. For instance, collaborative robots or ‘cobots’ work alongside humans, improving capabilities and safety. Robotic Process Automation (RPA) manages repetitive tasks, freeing up human resources for other tasks. AI’s potential to foresee demand trends has streamlined supply chain management. Automated visual inspection tools using AI identify errors rapidly and accurately, thus accelerating product development by analyzing data from manufacturing processes. The integration of AI into manufacturing offers myriad benefits for industry leaders to optimize operations, reduce costs, and improve productivity.

Leapfrogging in Emerging Economies

Emerging economies, much like the previously discussed African agricultural sector, have the opportunity to leapfrog into AI-enabled manufacturing. Nations with young, growing populations, like India, can harness their demographic advantage to spur AI adoption in manufacturing. The Fourth Industrial Revolution (I4.0) promises to transform various societal aspects, with AI at its core.

Industrial Artificial Intelligence (IAI) leads the way in the digitization and deployment of smart machines and technologies in the era of Industry 4.0. These include AI, machine learning, sensor networks, and the Internet of Things. The degree of transition towards I4.0, however, varies across sectors with the specific applications of IAI posing both unique issues and offering potential solutions that are often industry-specific. Researchers aim to shed light on these industry-specific concerns and the corresponding solutions, providing valuable insights for managers and decision-makers involved in the transition to I4.0.

In the modern information age, data is considered a critical asset for companies vying for a competitive edge. ‘Smart manufacturing’, a concept embodying the use of data-learning smart machines and processes to optimize production with minimal to no human intervention, has emerged as a key aspect of I4.0. AI technologies, particularly when combined with machine learning, form the bedrock of the cyber-physical systems that underscore I4.0. However, there exists a notable gap in research concerning how different industries have harnessed AI for their I4.0 journey, the challenges they’ve faced, and the potential solutions they’ve discovered. The research highlighted in the paper aims to address this void by discussing the applications of IAI across various sectors and presenting an IAI adoption pipeline that includes data collection, processing, model construction, and interpretation of results.

According to a McKinsey report, AI could boost the manufacturing sectors of emerging economies by trillions of dollars by 2030. These regions, despite lagging in previous industrial revolutions, have the opportunity to leapfrog into a new era of industrial development by embracing AI and other Industry 4.0 technologies.

Crucial Considerations

While embarking on the AI journey in manufacturing, two key areas need attention: workforce upskilling and ethical concerns. Upskilling the existing workforce to develop computational, logical, and numerical skills is crucial to meet the demand for AI-related jobs. Ethical policies need to ensure transparency, accountability, and safety while promoting inclusive AI development.

For successful AI integration in manufacturing, leaders should consider not only AI capabilities but also its responsible use. Microsoft emphasizes its role in fostering collaboration with customers, partners, and industry leaders to form a collective and responsible approach to AI integration. They aim to provide guidance and share their insights and perspectives as manufacturing and other industries navigate the shift towards more AI-driven operations.

Incorporating AI in manufacturing brings challenges alongside its benefits. The risk of deepening inequality, particularly if AI becomes primarily accessible to large corporations, is a significant concern. Ensuring AI transparency and focusing on sustainability and fair labor is as crucial as efficiency. Addressing these issues necessitates understanding risks, creating regulatory frameworks, adhering to ethical guidelines, and pursuing continuous research for a future where AI supports equitable, sustainable industrial practices.

Conclusion

In conclusion, AI holds the potential to revolutionize manufacturing, much like its transformative impact on agriculture. We’ve ventured into the future, picturing an era of ‘intelligized’ manufacturing powered by AI. In this technological leap, we must address challenges of workforce upskilling, ethics, and potential inequalities. The journey to AI integration is as much about managing these challenges responsibly as it is about leveraging AI’s capabilities. Microsoft and other leaders aim for a future of manufacturing that’s not just efficient, but also equitable, sustainable, and transparent. As we move forward, let’s not just transform our manufacturing processes but also uplift the very society they serve.

How can NuBinary help?

NuBinary can help your company with AI strategy and through the entire software development lifecycle. Our CTOs are capable of figuring out the best technology strategy for your company. We’ve done it several times in the past, on a big range of different startups, and have all the necessary knowledge and tools to keep your development needs on track, either through outsourcing or hiring internal teams.

Contact us at info@nubinary.com for more information or book a meeting to meet with our CTOs here.

%20-Aug%2016th-1.png)